In furniture production, you can not do without such material as natural veneer. This material is obtained by cutting a thin layer of wood from the trunks of various tree species. Veneer can be natural and artificial. Natural veneer is valued in the wood market, as it has significantly higher levels of characteristics, because it is not processed in production.

Natural veneer is popular and used in modern furniture production very often.

Natural veneer has several advantages:

- Simplicity in the production process, the whole production consists in correct, high-quality cutting of the sheets of the necessary material size;

- High strength;

- Long service life;

- Originality and uniqueness of the drawing;

- Variety of color palette;

- Excellent aesthetic properties;

- High water resistance;

- Ease of material;

- Originality and elegance.

In addition, the veneer has an absolutely ecological and natural appearance, which is given to it by the presence of knots, cracks, etc.

Natural veneer, it would seem to be quite simple to make, but in order to properly trim, at the right angle and in the future receive a veneer with a special appearance you need the hands of true professionals who work at Euroshpon- Smysha. Modern technologies, new equipment and master-specialists make it possible to receive only high-quality products, which occupy the first places in the wood products market, both in Ukraine and abroad.

«Euroshpon-Trade» company is a direct representative of «Euroshpon-Smyga» in the market and offers sliced veneer of various types of wood at the best prices.

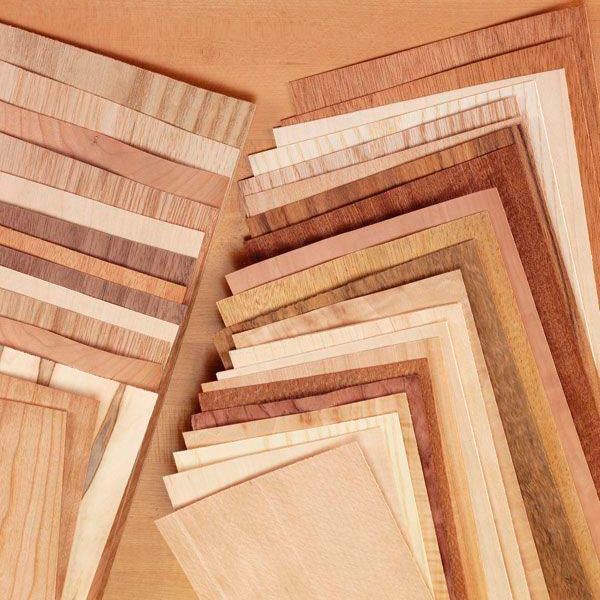

Types of natural veneers

Depending on the method of production, veneers are divided into several types, each has its own unique properties and aesthetic qualities.

By cutting from the barrel of thin strips, where their width corresponds to the width of the workpiece, a natural planed veneer is obtained. Its thickness is from 0.2 to 5 mm.

For the production of veneer, a veneer is used. For the production of this type of veneer, more valuable tree species are often used, which have a beautiful texture – oak, acacia, walnut, mahogany, ash, birch, etc. This kind of veneer is the most popular, because it is on it that all the beauty of wood species is visible. Each sheet of material has its own unique texture, due to the fact that the angles change with respect to the transverse or longitudinal workpiece. Sliced veneer is widely distributed in furniture production.

The lowest price is usually for peeled veneer, it has a standard texture, which does not make it unique. Obtain such a veneer by cutting from the outer edge of the log a solid and thin layer of wood when it rotates. The chopped natural veneer does not have any special texture qualities, but it retains high strength. The thickness of such veneers from 0.1 to 10 mm, for production use alder, birch, oak or pine. The production takes place on the lathe machines.

Another version of natural veneer is sawn veneer. This veneer is known for more than one hundred years, and is considered a real reproduction of art. The thickness of the sawn veneer from 1 to 10 mm, produces it most often from coniferous species: spruce, fir, cedar. Veneer is produced on veneer machines or horizontal sawmills. This veneer has unique high properties. Use it for musical instruments, as well as elite decorative finishes.

Types of natural veneer according to the method of cutting wood:

- R – radial type, annual rings cover all material, parallel to each other;

- SR – semi-radial, annual rings cover the veneer sheet by 75%, not more than;

- T – tangential, year rings take the form of a cone or simply curve bands;

- TT – tangential-end, year rings take the form of ovals.

The main wood species of natural sliced veneer

In the production of natural veneer, more than 300 species of wood are known, which are used, but 11 species are the most popular and available.

| Wood species | Color of veneer | Veneer Properties | Using veneers |

|---|---|---|---|

| Birch | From light yellow to light brown | Beautifully dyed and tinted; Weak resistance to moisture; Annual properties are poorly expressed | Interior doors, furniture industry |

| Karelian birch | Beige with dark brown dots and patterns | Rare and expensive material | Mosaics, ornamental material, inlays |

| Cherry | Russet | Excellent for any processing, including polishing | Furniture industry, manufacturing of exclusive products |

| Walnut | Light or dark brown | Is amenable to any processing | Furniture industry |

| White Oak | From light brown to sandy | High level of strength; Can be processed | Furniture industry, cladding of parquets and steps |

| Pine | Light with a homogeneous structure | Resistance to fungi; Low wear resistance | It is used in furnishing of furniture (economy class) |

| Maple American | From light to dark brown | High wear resistance | Applies to the finish of the floor |

| Anegri | From white-brown to sandy-brown with a pronounced gloss | Excellent color and polishing | Used in the manufacture of furniture and musical instruments |

| Bubing | From violet-red to brown | High Strength | Manufacturing of elite furniture |

| Makore | Red | High Strength | Furniture production and door cladding |

| Wenge | Dark brown with a light base | Resistance to pressure and loads | It is used in finishing the house and furniture (elite class) |

Natural sliced veneer does not undergo treatment with dyes or other preparations, it is the same as it came off the machine. It is this aesthetic property of the material that is so valued in the furniture industry. Natural veneer is perfectly combined with other materials, such as glass, stone or other types of trees. The environmental friendliness and sophistication of this material made it popular in the wood market.

«Euroshpon-Trade» company offers natural high-quality sliced veneer from different types of wood and at an affordable price. You can contact our managers and get the necessary information individually.