Purchase of veneer, storage and types of designs

Veneer, as a material for furniture production must be of high quality, so that the products have served for many years and had a beautiful appearance. The quality of veneer depends not only on its production, but also on storage. Therefore buying furniture veneer involves checking the storage conditions to obtain the required high quality product.

Buy veneer

Purchase veneer can be made as packs and individual sheets. When storing the sheets of veneer are put in a certain order to ensure the compatibility of patterns. When selling veneer is not taken from the middle of the pack in order not to violate the order.

Before buying veneer should calculate the required area of veneer depending on the surface for further coating and make sure to allow waste when cutting the sheet. It is better to make a mistake in a big way, as each sheet is different in its uniqueness, and if you need to buy the material, it is not always possible to get a suitable veneer pattern.

Evaluation of the sheets takes place depending on the area of the material, sometimes you can find already cut pieces of standard sizes at a certain price. It is possible to buy separate packs of an interline interval of specially selected sheets for marquetry production.

Transport and storage of veneer

In order to maintain the technical and aesthetic performance of the veneer, the important step is the transportation of the veneer, veneer sheets are usually rolled into rolls, this is done very carefully, often to avoid breakage of the sheet, the material is slightly moistened, this makes it possible to pack it most safely or delivered in packages in their original condition.

Deploy such rolls are also recommended slowly and carefully, veneer is a fragile material, and it is necessary to fear that it is not cracked and broken. It happens that there are cracks at the edges of the sheets, they must necessarily seal a special adhesive tape of paper, so that they do not get dirt, especially for light wood.

How and when packing and when unpacking it is advisable to moisten the veneer. At this stage it is necessary to level it. You can hold on a few material, and it is possible to moisten it with water and placed between two smooth surfaces of the panels. Long time keep him in there is not worth it to not have mold.

If you bought the veneer, but don’t want to use it, it must be properly stored. It is recommended that the dark room so that the tree does not darken or Shine, cover the veneer is necessary from dust and dirt, as well as provide ventilation. A high level of humidity is not allowed in the room where the veneer is stored.

our employees are always ready with pleasure to advise you, and also will help to calculate necessary quantity veneer for veneering work. Our clients appreciate us for professional approach and high-quality service. By choosing us, you get individual approach, reasonable prices and valuable advice from a team of professionals.

Used parts of wood for veneer production

There are a lot of varieties of veneer, it depends on the selected raw materials. Difference carries the picture, pattern veneer, which may depend on the type of wood, method of production, what part of wood made veneer.

For the manufacture of veneer use such part of the wood:

- Branching;

- Trunk

- Cap;

- Bottom tree trunk.

Types of veneer patterns

|

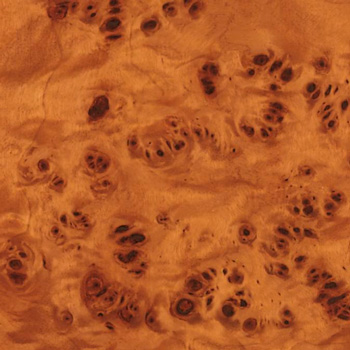

cap is a growth on a tree, it can often be found on trees such as aspen, black alder and walnut. Most often it can be seen on the birch. This wood is a valuable material, so veneer is quite expensive, but its characteristics give the products in the furniture industry a certain charm and beautiful aesthetic appearance.

Often this veneer is used in the manufacture of small wooden products (canes, boxes, bowls). The non-standard size sheets from 150х100 1000х450 mm to mm. |

|

the Trunk or stump is the lower part of the tree trunk, the plank from this part of the tree is called Komleva. Veneer from such raw materials is obtained with unique patterns, aesthetically it looks expensive, and has an affordable price. |

Veneer with unique, atypical patterns is made of broad-leaved wood when processed on a peeling machine. Known types of veneer as bubble, quilted, maple “bird’s eye” . |

When using a tree with wavy layers, get wavy veneer pattern, where dark stripes alternate with light. Often such veneer is used in the production of musical instruments. |

the Svilevatoj wood veneer — veneer from the tree, which is called the fork is also different, get a pinnate pattern. The dimensions of such sheets of veneer can be a length of 300-1000 mm, a width of 150-200 mm. |

Interesting patterns on veneer-is “lace” and “spray” , such veneer can be obtained only from oak or sycamore with a certain method of sawing, for example, when cross-layered cutting get the same patterned web – “lace”. |

Such a method of cutting as dome — tangential planing against annual rings gives a pattern in the form of ovals and bends, such veneer is most common in furniture production, it is also used in panel wall treatment. Sheets of such veneer are produced in size – 2400 mm and longer, 225-600 mm wide. |

|

Veneer can be natural, but artificially colored, this treatment is mainly amenable to veneer of light wood, such as sycamore (hare tree), the color is made by special chemicals in shades of gray or silver. Impregnate such veneer under high pressure to the maximum to give it quality characteristics and beautiful aesthetic appearance. | |

Euroshpon-Trade offers a wide range of sliced veneer from different types of wood for every taste. Acquired from us veneer will delight you with the unique pattern and quality of production. Our conditions are convenient and profitable for both small and large enterprises. We work for you!